Summer can be the most energy-intensive season of the year—especially for grocery stores and restaurants. When outdoor temperatures rise, refrigeration systems work harder, kitchens get hotter, and customers expect cool, comfortable environments. The result? Soaring energy costs that cut into your profit margin.

But the good news is that food businesses have plenty of opportunities to reduce their energy usage without compromising service or food safety. From HVAC optimization to smarter refrigeration and lighting choices, this blog shares seven proven ways to cut energy costs in summer—perfect for busy grocery stores, convenience shops, and restaurants.

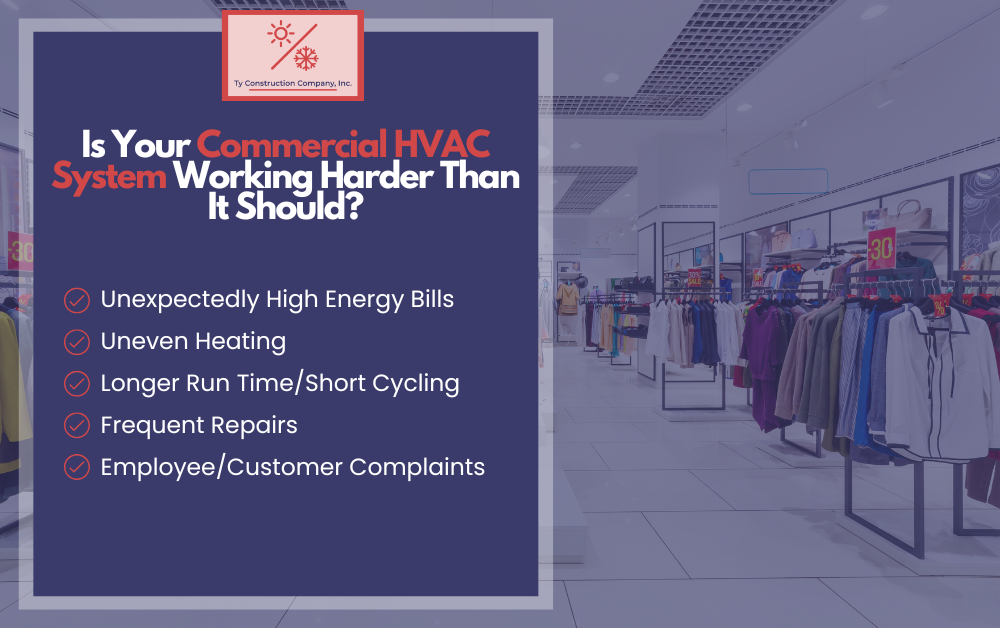

1. Optimize HVAC Performance

Schedule Mid-Summer HVAC Maintenance

One of the most important steps any food business can take is making sure the HVAC system is in top shape before the hottest days of the year hit. A mid-summer tune-up can prevent breakdowns, improve efficiency, and help you identify small issues before they become big problems. Cleaning coils, checking refrigerant levels, and calibrating thermostats all make a difference.

Clean Filters & Coils Regularly

Dirty air filters and coils can significantly reduce the efficiency of your cooling system. Filters should be cleaned or replaced at least once a month during peak seasons, and coils should be inspected quarterly to ensure they’re free from dust, debris, or grease buildup from nearby kitchens.

Set Smart Thermostat Zones

Different areas of your facility have different temperature needs. Prep kitchens and dishwashing areas run hotter than dining rooms or offices. Use programmable thermostats to zone control your building’s temperature—and avoid cooling areas that don’t need it. Just a few degrees of adjustment can lower your utility bill by 3–5%.

Pro Tip: Use ceiling fans in dining rooms or retail aisles to keep air moving and improve customer comfort without relying solely on the AC.

2. Maintain & Upgrade Commercial Refrigeration

Inspect Door Seals and Gaskets

If your walk-in coolers or display cases are leaking cold air due to cracked gaskets or misaligned doors, you’re wasting a lot of energy. Poor seals force compressors to work overtime, which shortens equipment lifespan and spikes your electricity bill.

Defrost Freezers on a Schedule

Manual and automatic defrost systems should be regularly checked for ice buildup. Excessive frost adds insulation and forces your system to work harder to maintain set temperatures. Keeping your defrost cycle optimized ensures consistent performance.

Upgrade to ENERGY STAR Refrigeration Units

If you’re using older refrigeration models, now is the time to look into energy-efficient replacements. ENERGY STAR-rated commercial refrigerators use up to 50% less energy compared to outdated equipment. Bonus: many utilities offer rebate programs for upgrading to more efficient units.

Bonus Tip: Use night curtains on open refrigerated display cases to trap cold air when the store is closed.

3. Install or Fine-Tune Your EMS/BAS

What’s an Energy Management System?

An EMS (Energy Management System) or BAS (Building Automation System) allows you to monitor, control, and automate your energy use in real-time. These systems are especially valuable in multi-zone operations like large restaurants or grocery stores.

Benefits of Real-Time Energy Monitoring

By seeing exactly how and when you’re using electricity, you can identify equipment that’s running unnecessarily—or adjust operations during peak demand hours. Alerts can help you spot spikes before they lead to service interruptions.

Use It to Automate Cooling, Lighting, and Cooking Schedules

Schedule systems to shut off lights, reduce AC use, or idle unused equipment during slow hours. Smart scheduling helps you avoid costly overlap in cooling and cooking operations—especially during non-peak times.

4. Switch to LED Lighting (Inside & Outside)

Replace Fluorescent or Incandescent Bulbs

Lighting contributes a significant portion of a food business’s energy usage—and heat. LED lighting consumes up to 75% less electricity and produces much less heat, helping your HVAC systems work more efficiently.

Use Motion Sensors in Storage Areas and Restrooms

Installing motion sensors or timers in low-traffic areas can drastically reduce waste. Lights don’t need to stay on in the walk-in freezer or back hallway when no one’s around.

Upgrade Outdoor Signage to LED

Exterior signage and parking lot lighting can run all night long. Switching to LED alternatives ensures lower utility bills while maintaining visibility and safety.

Bonus: LEDs last up to 25x longer than traditional bulbs, reducing replacement costs.

5. Control Kitchen Equipment Energy Use

Turn Off Idle Equipment

It’s common for restaurants to leave fryers, griddles, and ovens running throughout the day—even when not in use. Create a daily SOP for when to power up or down specific appliances. For example, delay starting certain cook lines until business picks up in the evening.

Use High-Efficiency Ovens, Fryers, and Griddles

Modern ENERGY STAR-rated commercial kitchen equipment uses 20–30% less energy than standard models. High-efficiency appliances often include built-in sensors and quick-recovery technology, which means they don’t need to run constantly to stay hot.

Stagger Cooking Times

Avoid turning on multiple pieces of equipment at once, especially during peak utility hours. Staggering prep times can reduce energy spikes and lower your demand charges.

Tip: Train kitchen managers to monitor energy-intensive operations and adjust practices as needed.

6. Seal Up the Building Envelope

Inspect for Drafts in Loading Zones and Entrances

One often-overlooked source of energy waste is air leaks. Loading docks, customer entryways, and receiving areas can all allow hot air in—and let your cool air out. Use air curtains or vestibules in high-traffic areas to prevent temperature swings.

Add Weather Stripping and Automatic Door Closures

Simple additions like weather stripping on walk-in coolers or door sweeps on back entrances can drastically improve your building’s insulation. Automatic closers reduce the chance of doors being left ajar.

Insulate Refrigeration Lines and Roof Access Areas

Heat infiltration from rooftops or uninsulated mechanical rooms adds to your overall energy burden. Insulating these areas can reduce the load on your cooling and refrigeration systems.

Long-Term Tip: Consider reflective roofing or window films to further reduce indoor heat gain.

7. Promote a Culture of Energy Awareness

Train Staff on Energy Best Practices

Your energy strategy is only as strong as your team. Train employees on daily habits that contribute to energy savings—like shutting cooler doors quickly, turning off lights when not needed, or reporting malfunctioning equipment.

Use Energy Scorecards or Incentives

Friendly competitions between shifts or store locations can boost morale and accountability. For example, reward the team that lowers their weekly utility usage the most.

Display Reminders for Turning Off Equipment

Place visual cues in prep areas, offices, and walk-ins to remind staff about key energy habits. Reinforcement leads to consistency.

Why it matters: A motivated and aware team can make small adjustments that save thousands over the summer.

Smart Energy Savings Start Today

Running a food business in the summer is challenging enough—your energy bill shouldn’t make it harder. By taking a proactive approach to HVAC, refrigeration, lighting, and equipment use, you can cut energy costs in summer while maintaining performance and comfort.

Even implementing just 2–3 of these strategies can lead to noticeable energy costs savings. Over time, those energy costs savings grow—and help fund the upgrades and services that make your business more efficient year-round.

Need help making your building or kitchen more energy-efficient?

Ty Construction can help you upgrade HVAC, optimize refrigeration systems, and fine-tune your EMS setup for real savings this summer.